25 Years Focused On Rubber Parts

In 20 years of development history, Bo UNITA has always focused on the field of automotive rubber parts, products widely used in automotive body systems, steering systems and electrical systems ......

A high-end production equipment at home and abroad to ensure the quality

Austria has imported liquid silicone rubber ENGEL injection molding machine; Using automatic dosing machines, automatic testing equipment, automatic crimping machine;

Synchronous Design

Host plant synchronous developmentAbrasive Tool Developemnt

Development&manufactring centerEnvironmental Protection

Through environmental certification

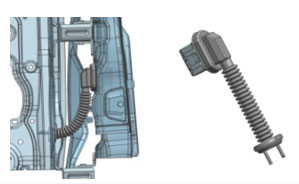

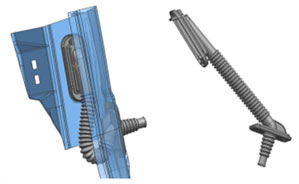

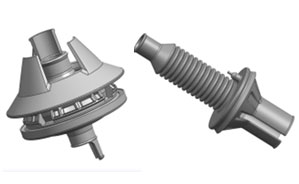

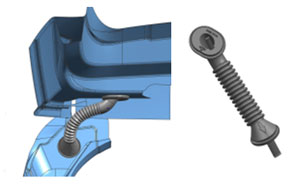

Rubber Parts

Rubber processing, the process will be made of rubber of rubber products. All the basic process of rubber process

Read more

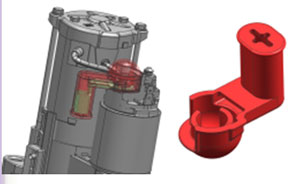

Plastic-Parts

Rubber processing, the process will be made of rubber of rubber products. All the basic process of rubber process

Read moreIntegrated Solutions

Production equipment in our conpany25 years experience

Our company Founded in 1990, China!professional technical team

Development strategy and businessAbout Us

We have the certificates of IATF16949:2016, ISO14001:2015 and GB/T28001-2011. And we possess profile projector, vulcameter, ageing oven, ozone ageing chamber, hardness tester, force gauge and so on.

We have the certificates of IATF16949:2016, ISO14001:2015 and GB/T28001-2011. And we possess profile projector, vulcameter, ageing oven, ozone ageing chamber, hardness tester, force gauge and so on.

And our main products are widely used in automotive body system, steering system, electrical and electronic system. Recently, we have adjusted our development strategy and expanded our bussiness scope, developing and producing various plastic parts.

And our main products are widely used in automotive body system, steering system, electrical and electronic system. Recently, we have adjusted our development strategy and expanded our bussiness scope, developing and producing various plastic parts.

How We Work

There ase approximate 100 sets of production equipments in our company, such as computer numerical control(CNC).

Automatic dosing machine, internal mixer, open mill, automatic vulcanization press, injection molding machine.

We are able to implement the whole production process of rubber parts, from developing tolling, preparing recipe, internal mixing to vulcanization.

Various types of spare parts, Free of charge to provider samples

Download our sample or get more product samples by mail

- Rubber Parts

- TPE-TPV

- Plastic-Parts

Vulcanization Workshop

How Electric Cars Defeated Emis…

Our Partner

About Bowman

Manugacturer specialized in designing, developing and producing automotive rubber parts and silicone rubber parts. Founded in 1990.